PETG (Polyethylene Terephthalate Glycol) filament is a popular 3D printing material that combines the strength and durability of ABS with the ease of printing associated with PLA. It’s favored for its excellent mechanical properties, chemical resistance, and versatility.

Properties of PETG Filament

Material Composition: PETG is a modified form of PET (used in water bottles), with added glycol to make it less brittle and easier to process.

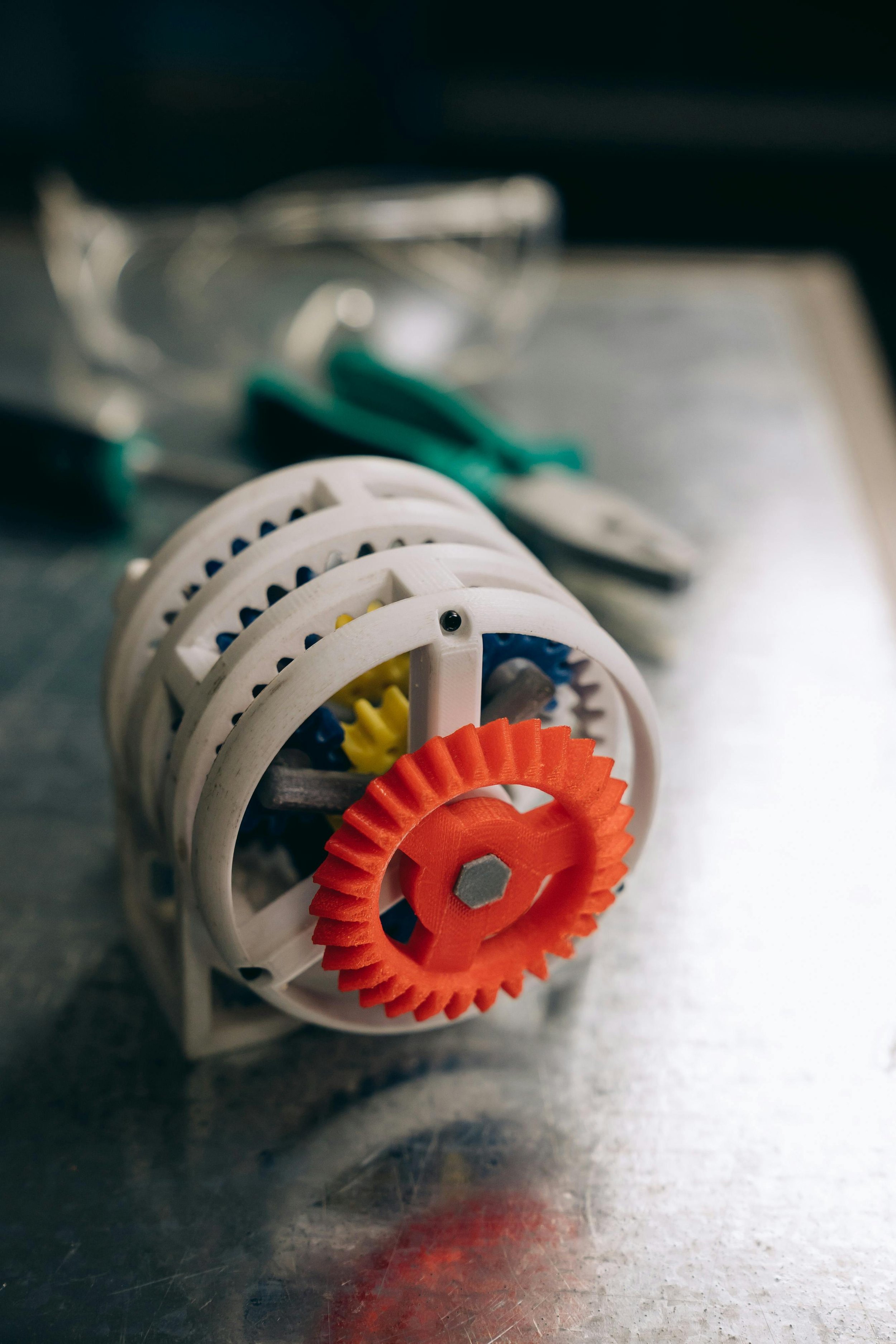

Durability: It offers high impact resistance, flexibility, and toughness, making it suitable for functional and mechanical parts.

Transparency: Many PETG filaments are naturally translucent, making them ideal for applications requiring a clear or glossy finish.

Chemical Resistance: PETG is resistant to water, acids, and alkalis, making it suitable for outdoor or chemical-exposed applications.

Advantages of PETG

High strength and flexibility, offering a good balance between rigidity and ductility.

Temperature resistance: Softens at around 80°C (176°F), outperforming PLA in heat tolerance.

Minimal warping and good layer adhesion.

Low odor during printing, with no harmful fumes.

Hygienic properties: Often used in food-safe applications when printed under controlled conditions.

Disadvantages of PETG

Prone to stringing and oozing during printing due to its high stickiness.

Slightly less beginner-friendly compared to PLA due to its sensitivity to print settings.

Can be challenging to sand or post-process because of its durability.

Common Applications

Functional prototypes and end-use parts.

Food and beverage containers (e.g., water bottles or storage boxes).

Outdoor items like planters or tools due to its UV and moisture resistance.

Mechanical parts requiring impact resistance, such as brackets or hinges.